What is the difference between static dissipative and conductive?

There is a lot of confusion over whether an ESD floor should be static dissipative or conductive. Unfamiliar with technical details, specifiers often require a floor to be conductive or dissipative, convinced one is better than the other. This is not the case and a floor should always be chosen based on the individual requirements.

What is the difference?

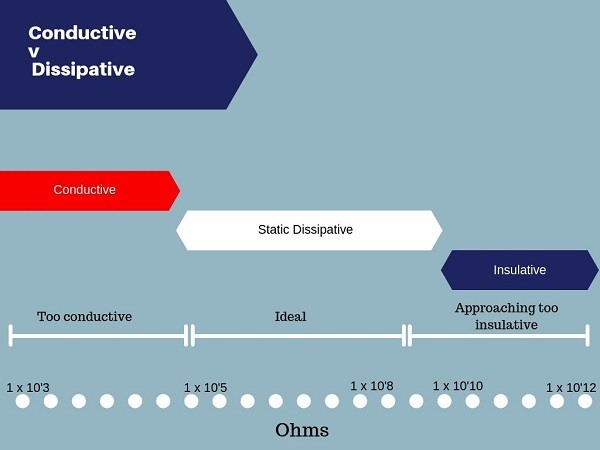

Conductive and dissipative are resistance categories used to describe the speed at which currents flow across or through a flooring material.

- Flooring materials measuring less than or equal to 1.0 x 10’5 are considered conductive

- Flooring materials measuring greater than 1.0 x 10’5 and less than or equal to 1.0 x 10’9 are considered static-dissipative.

To predict the speed at which an ESD floor will ground (remove) static charges, we measure the electrical resistance of the flooring material using an ohm meter.

The capacity of a material to slow, or resist, the flow of electricity is known as its resistivity. If resistance is low, static charge will flow quickly across the floor so it is classed a conductive.

If resistance is higher, the static charge will find it harder to move across the floor so flows in a slower, more controlled manner and is classed as dissipative.

Static dissipative or conductive -which is best for me?

Most ESD floors are installed to solve an existing static problem or to prevent a static problem occuring.

Static is very common within the workplace. When you walk across a man made carpet your body collects extra electrons. The electrons cling to your body until they can be released. As you reach and touch an object you get a shock as the surplus electrons are being released.

To perform properly, an ESD floor must meet two criteria:

- it must draw static electricity away from people or charged objects and conduct those charges safely and effectively to ground;

- it must prevent static generation in the first place.

Both a conductive and a static dissipative floor would meet these criteria however there are great differences between the two.

If a floor is too conductive the charge is removed so quickly it can travel across the surface of the floor, not into it, which could cause a harmful electric shock to a person in contact with the floor.

Conversely, if the floor is highly dissipative the charge will build up faster than it is being removed by the floor.

For safety and performance it is recommended to use flooring that falls mid range – between 1 x 10’5 and 1 x 10’8.

Most organisations set an upper limit on resistance values of 1.0 x 10’7.

Any flooring material that measures within this range of 1 x 10’5 and 1 x 10’8 will safely and effectively discharge static to ground.

Please contact us at [email protected] if we can help with any queries.